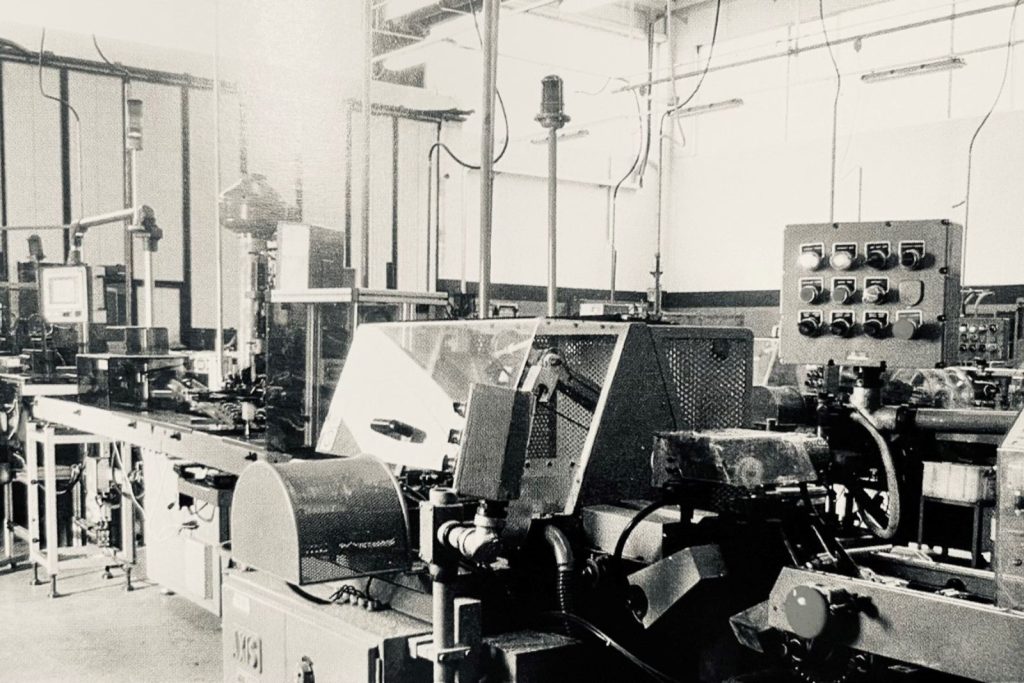

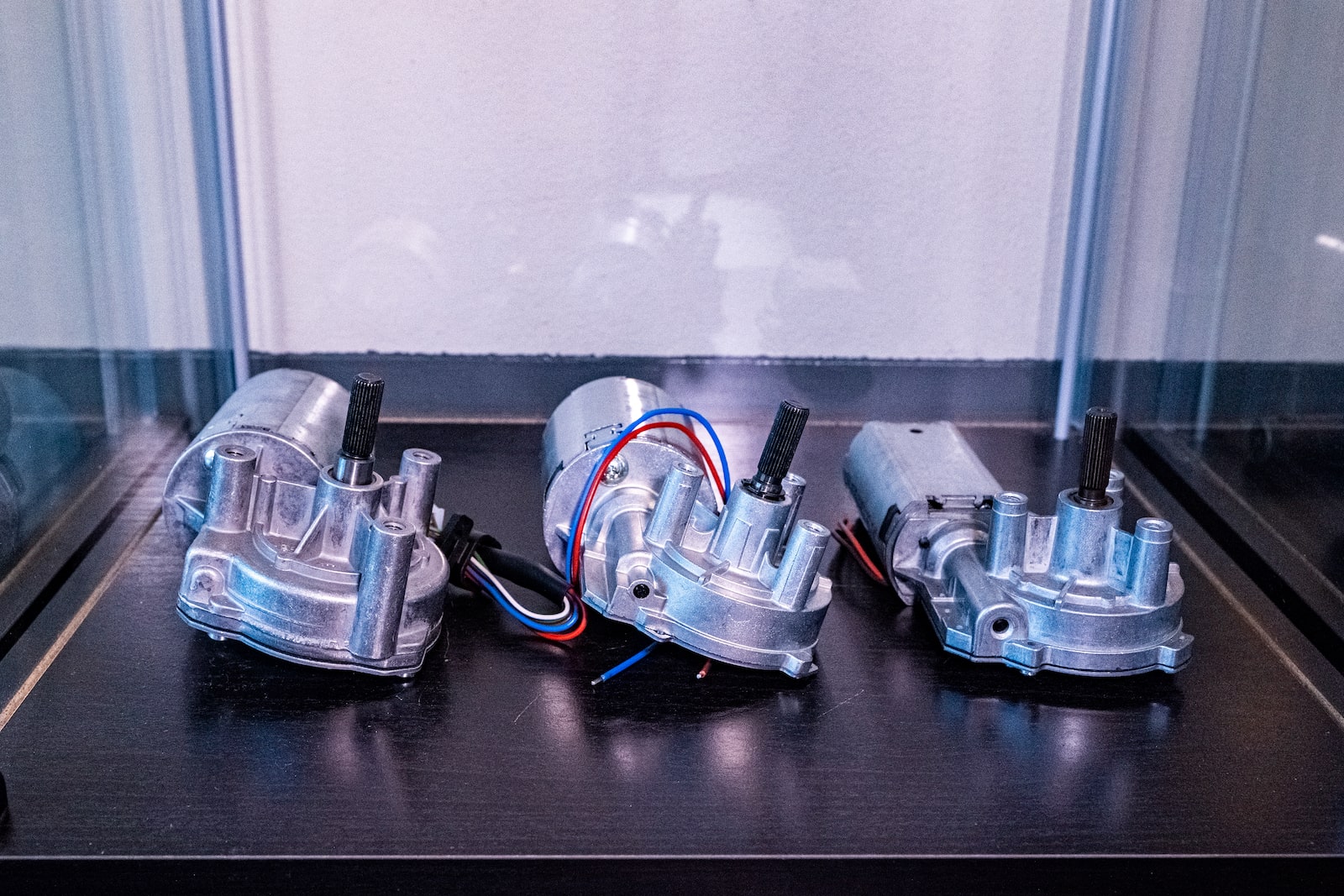

Electro-Parts is a family owned company founded in 1983 from a previous experience in DC Motor production. The Company development and growth have been achieved through continuous improvement of Quality and Customer Service. In Italy we design and manufacture our products, brushed and brushless motors, mostly for Automotive sector and Home and Office automation. Our purpose is to give all our Customers a qualified and global service by using the best solutions concerning either motors and gear-motors production.

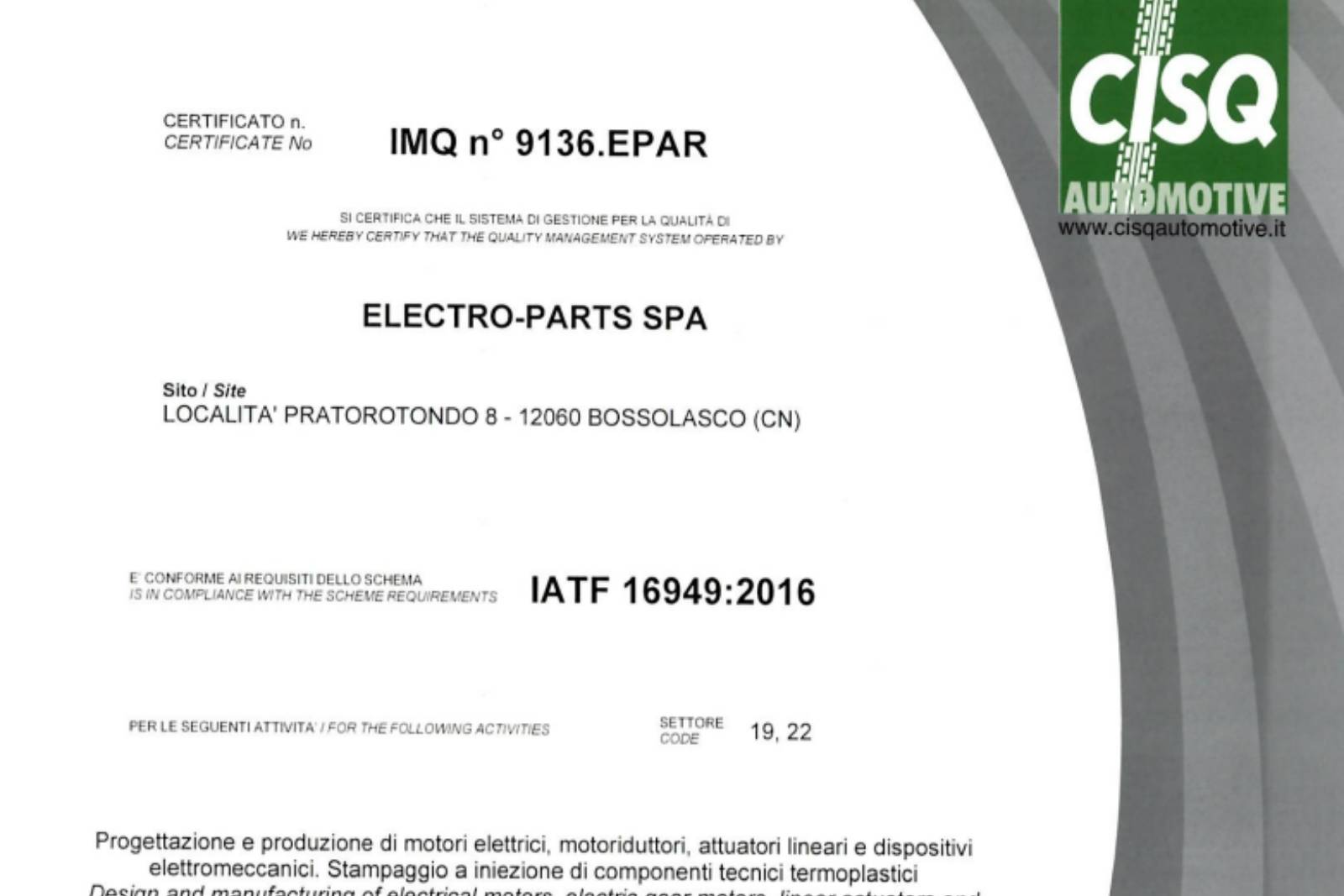

Thanks to productive synergies, a high flexibility and a qualitative standard corresponding to the requirements of the set of rules ISO 9001:2015 – IATF 16949:2016, Electro-Parts is able to satisfy all the requirements of its demanding Customers.

Electro-Parts is certified accordingly to ISO 9001:2015 and IATF 16949:2016.

Our financial position is certified by Moody’s.

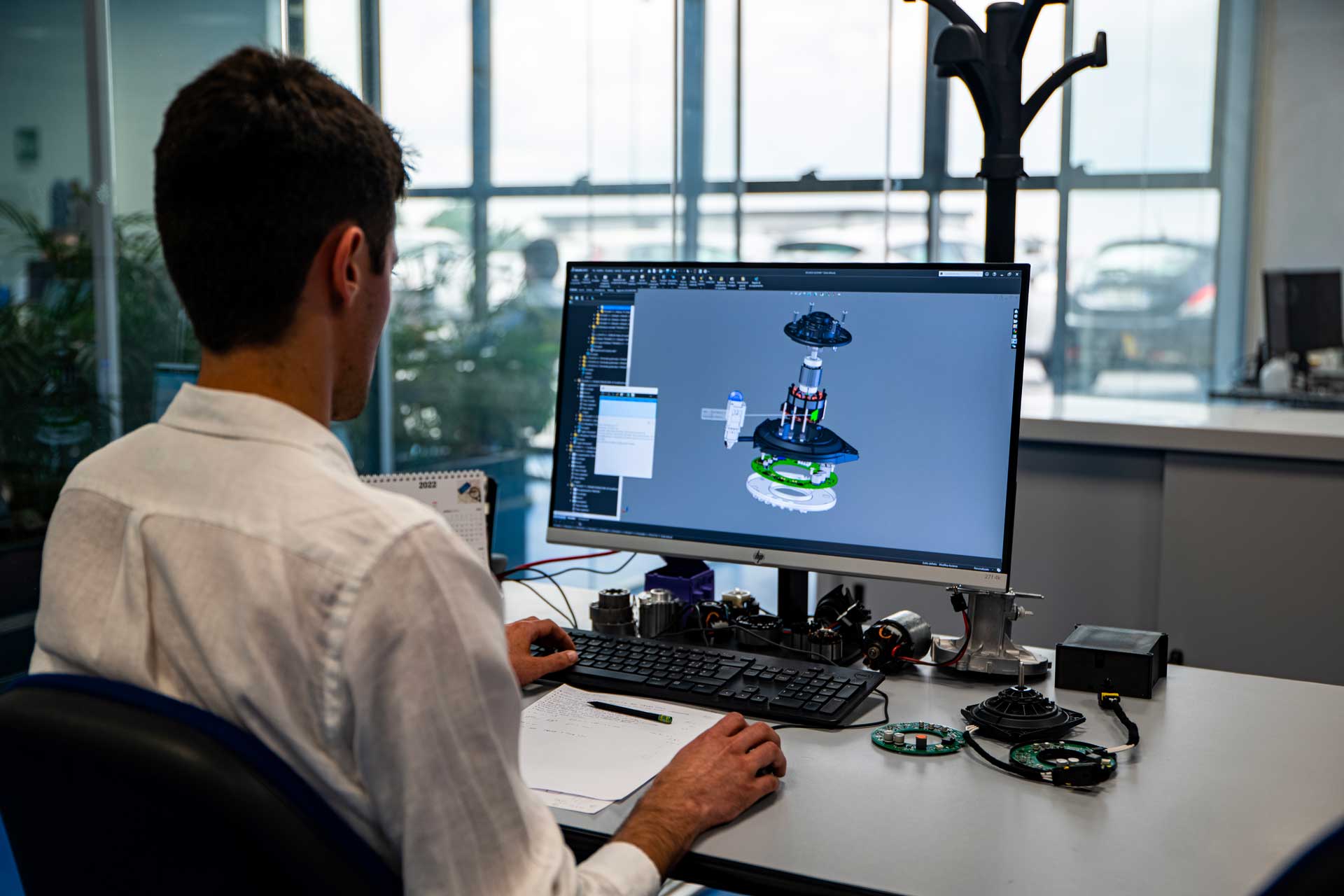

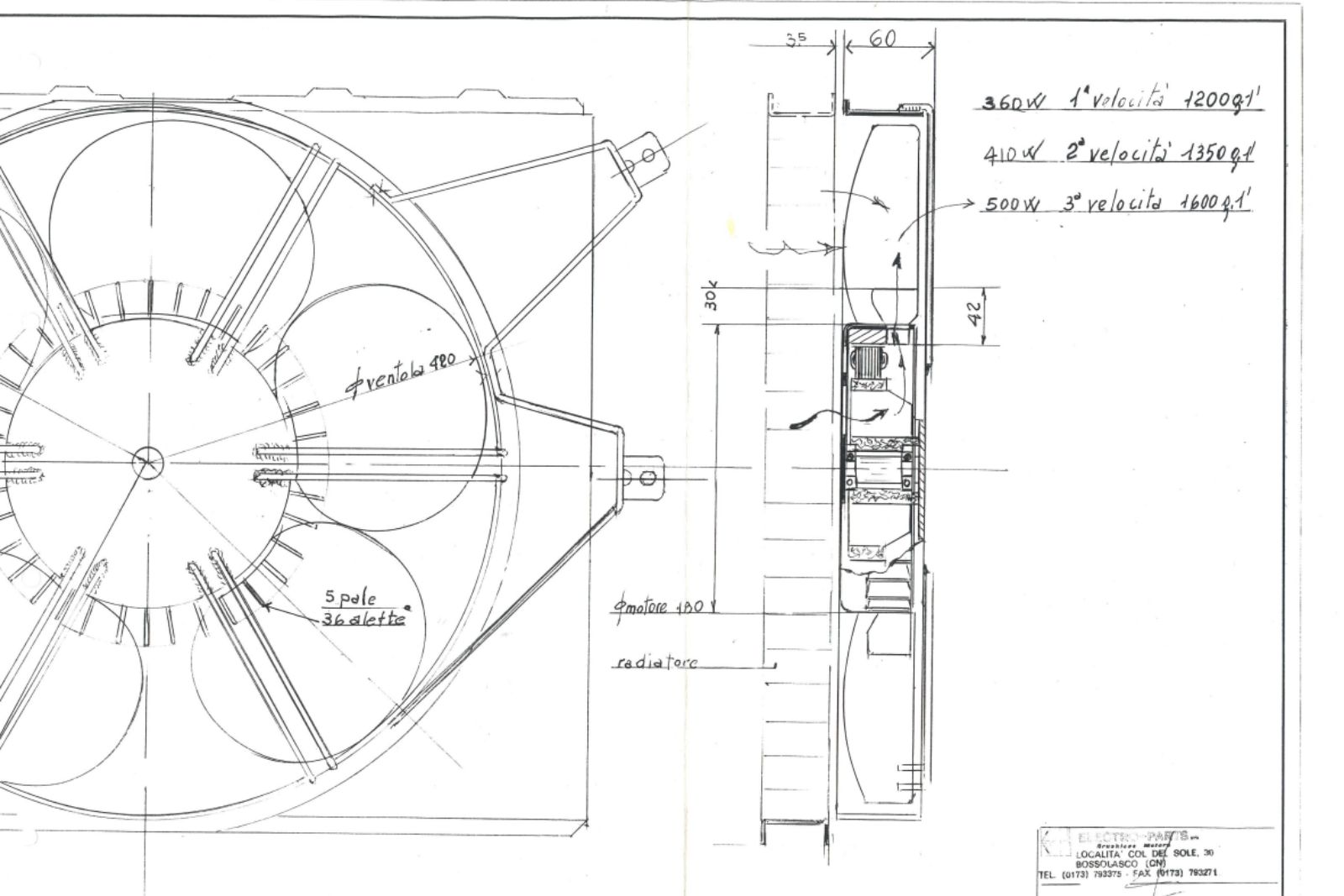

Starting from Customer Specific Requirements, Norms and Regulation of the final market our engineers are capable to support the customer and design the right motor to be integrated in the final application. Simulation tooling help us to identify the gaps in terms of noise, thermal behaviour and electromechanical performances minimizing the design costs and avoiding several loops of physical prototyping. The best results with the minimum time and cost effort!

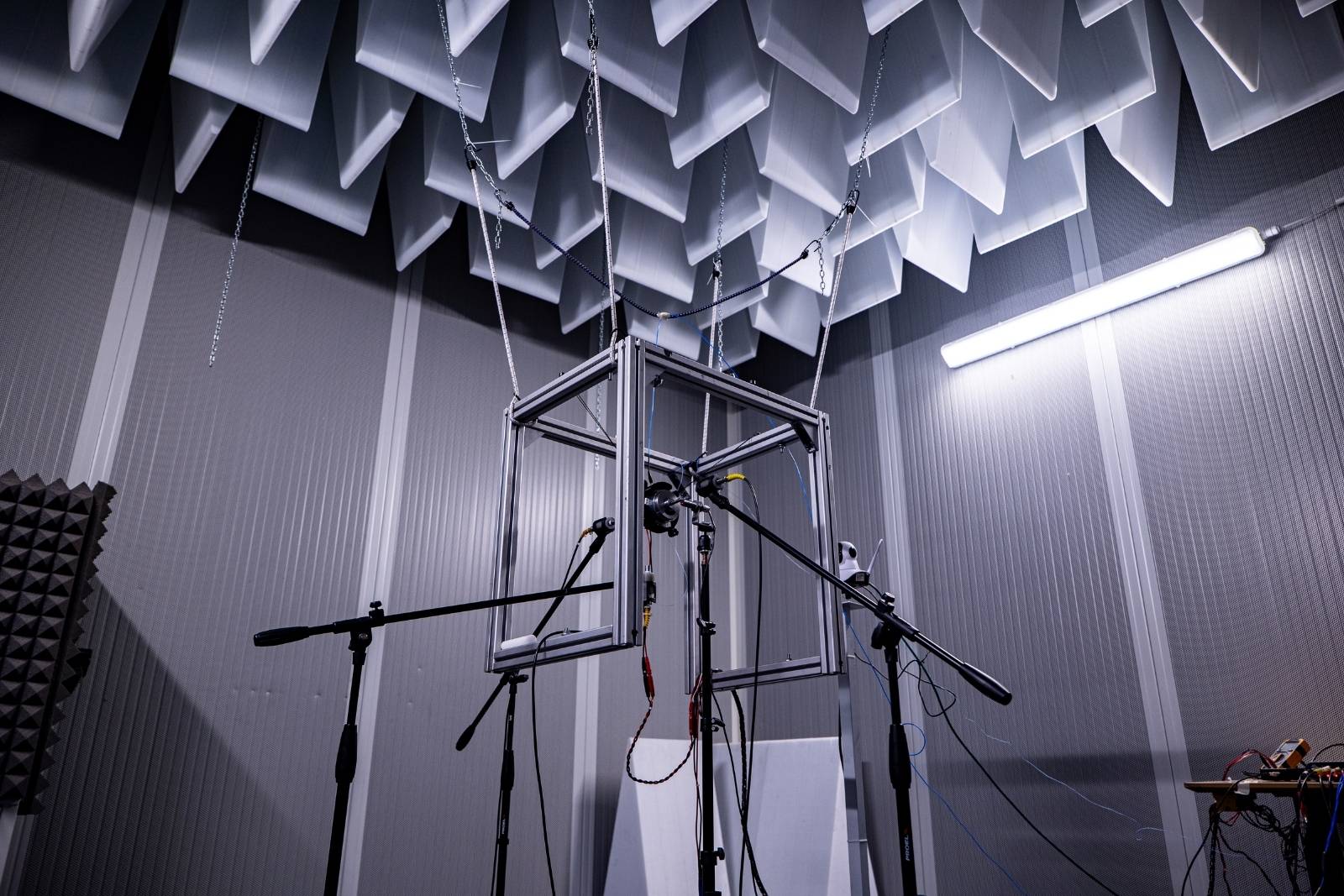

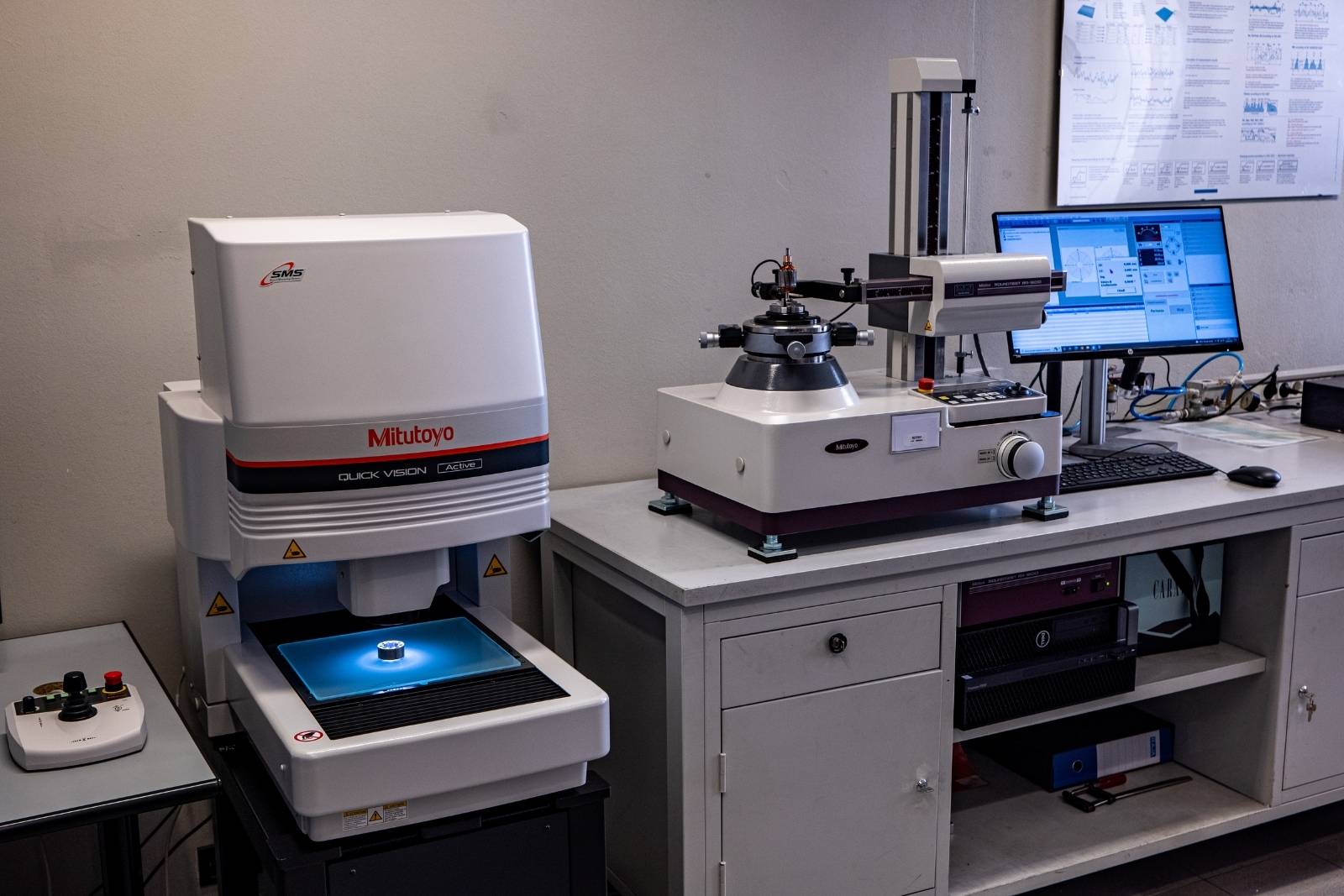

Once the product is defined, our testing engineering team will validate it accordingly to the Specification and the testing activities defined by Regulation and Customer Norms. Internal capabilities include thermal chambers, thermal shock, shaker in climatic chamber, semi anechoic chamber, IP testing, EMC chamber for preliminary testing and several benches to measure all physical parameters of the electric machine.

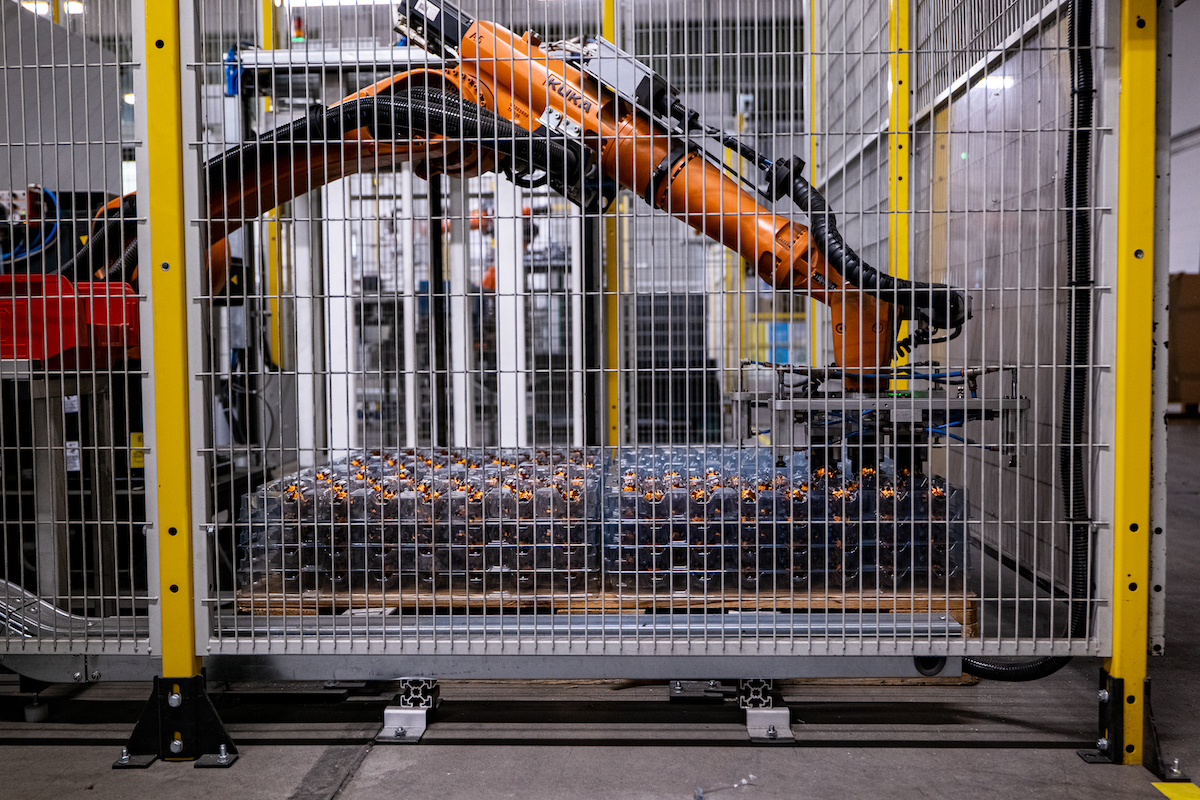

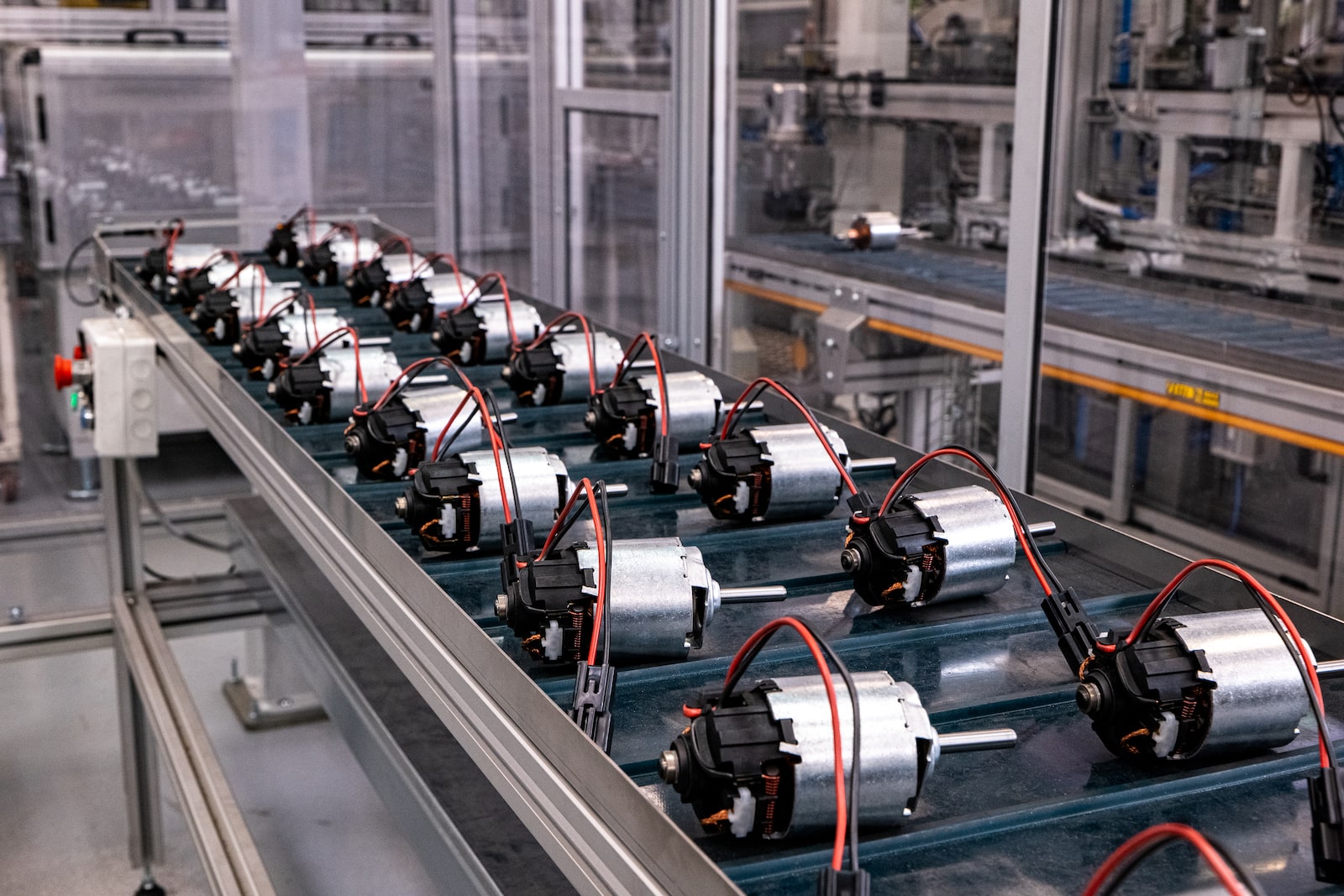

Our production plants in Italy and Romania, can serve our customers with the highest level of quality and service. Rotors are produced on fully automated lines that guarantee the punctual traceability of every single part. Motors are assembled on lines with different level of automatization to find the best compromise between initial investments and part price.

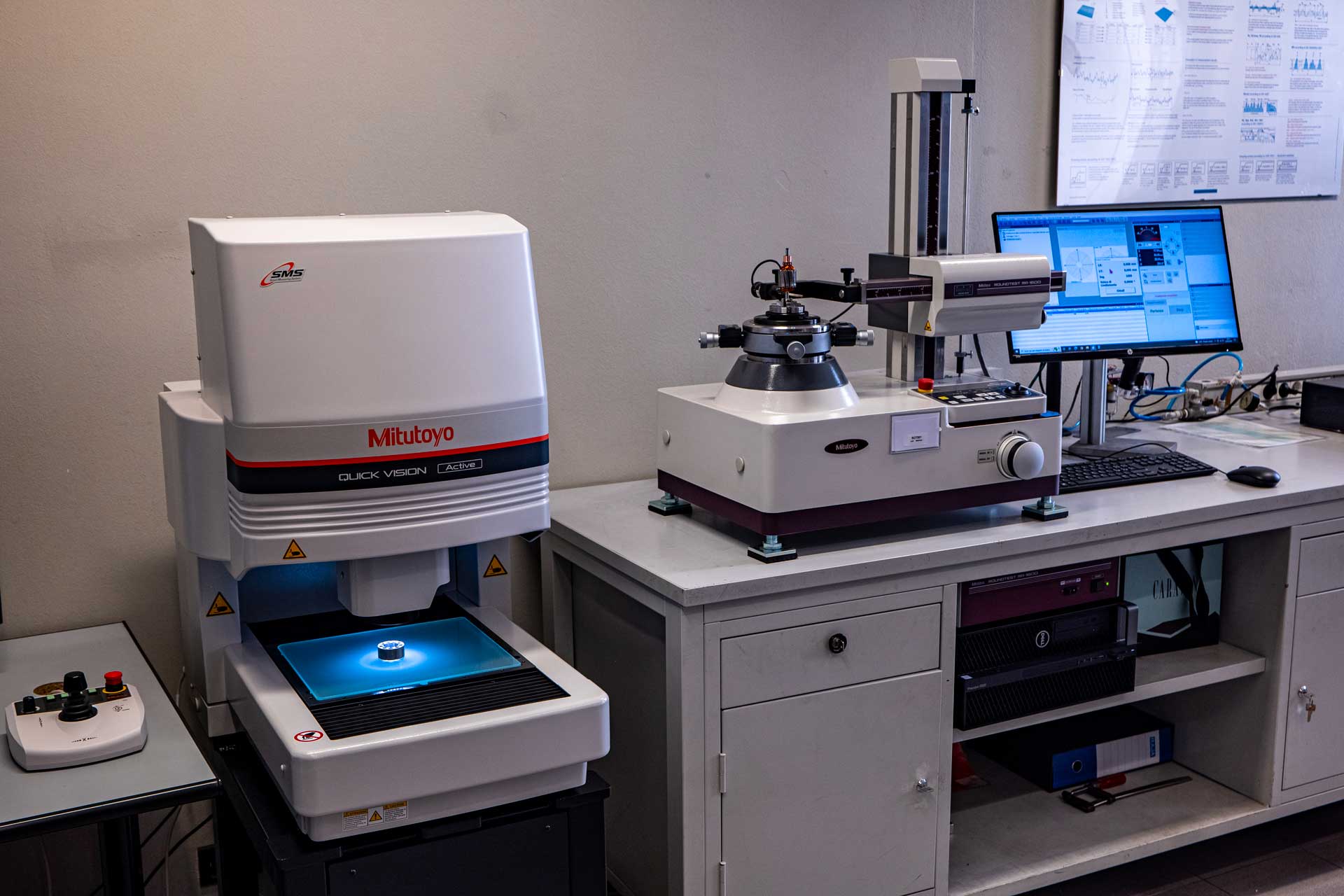

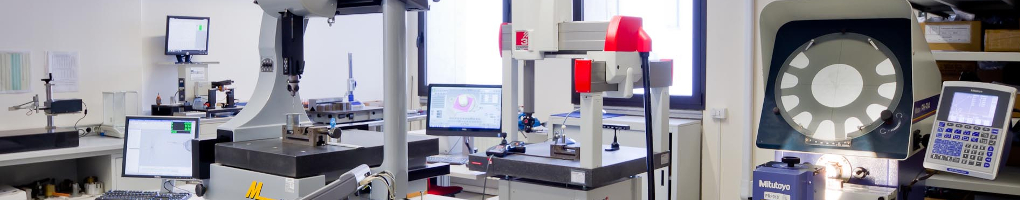

We collaborate with suppliers to define the critical characteristics and the capabilities that our metrology team controls during in-coming inspection based on the final application and the experience.Thanks to our integrated MRP we constantly monitor in-process parameters, EOL testing, OEE and scrap level to avoid any degradation of the assembly activities. We support the customer in case of any need.

Our Head Quarter is located in Bossolasco, in the North-West of Italy.

Our plant is in the heart of Langhe, a region awarded by Unesco as World Heritage.

Our second production facility is located in Baia Mare, in the North West of Romania. A strategic logistical crossroad to efficiently supply Central and Eastern Europe.

Our experience, acquired in different sectors, has made the company extremely flexible, competitive and innovative.

Our Engineering Team can support demanding customers with advanced and cutting-edge technology solutions.

In fact, we can count on in-house technical expertise to develop the most advanced products with an innate understanding of all aspects of mechanics, fluid dynamics, electronics, electro-magnetics.

In Electro-Parts, we want to grow the sustainability of our business, working with our customers on returnable packaging and recyclable solutions to solve customers problems without impacting the global Environment.

With enthusiasm and passion our Engineering team focus on more efficient motors, our production team on improvement of productivity to contribute to Environmental Conservation.

We have recently installed a solar farm and a new energy recovery system. They allow us to save 83 tons CO2 equivalent emissions per year.